For several decades, Vibrafloor systems have been in operation in more than 30 countries,

offering an avalanche of benefits to our customers.

The Vibrafloor system delivers the highest reclaim rates, on most types of products, free flowing or cohesive. This makes it particularly suitable for large storages and/or very short cycle operations.

The end result of a reclaim operation is a completely clean silo. No additional cleaning operation is required, which means that no Personnel has to be exposed to the hazardous atmosphere of the storage.

All vibrating parts are mounted on specially designed springs, which protect the storage structure from any residual effects. By also keeping the product unloading symmetrical, it does not require any reinforcement or particular provisions on the storage foundations and structure.

During the reclaim process, no effort or stress is introduced into the bulk product, which sees only its own weight. Hence, fragile products are preserved from any damage, and no dust is created.

Lastly, combining the efficiency of electric vibrators and the power of gravity, the energy consumption of the Vibrafloor system is very low. For a given volume and discharge rate, energy savings can be up to 5 times bigger than alternative systems available commercially.

The Vibrafloor system has a robust design, does not generate any stress on the structure, and is suitable for a wide range of product types.

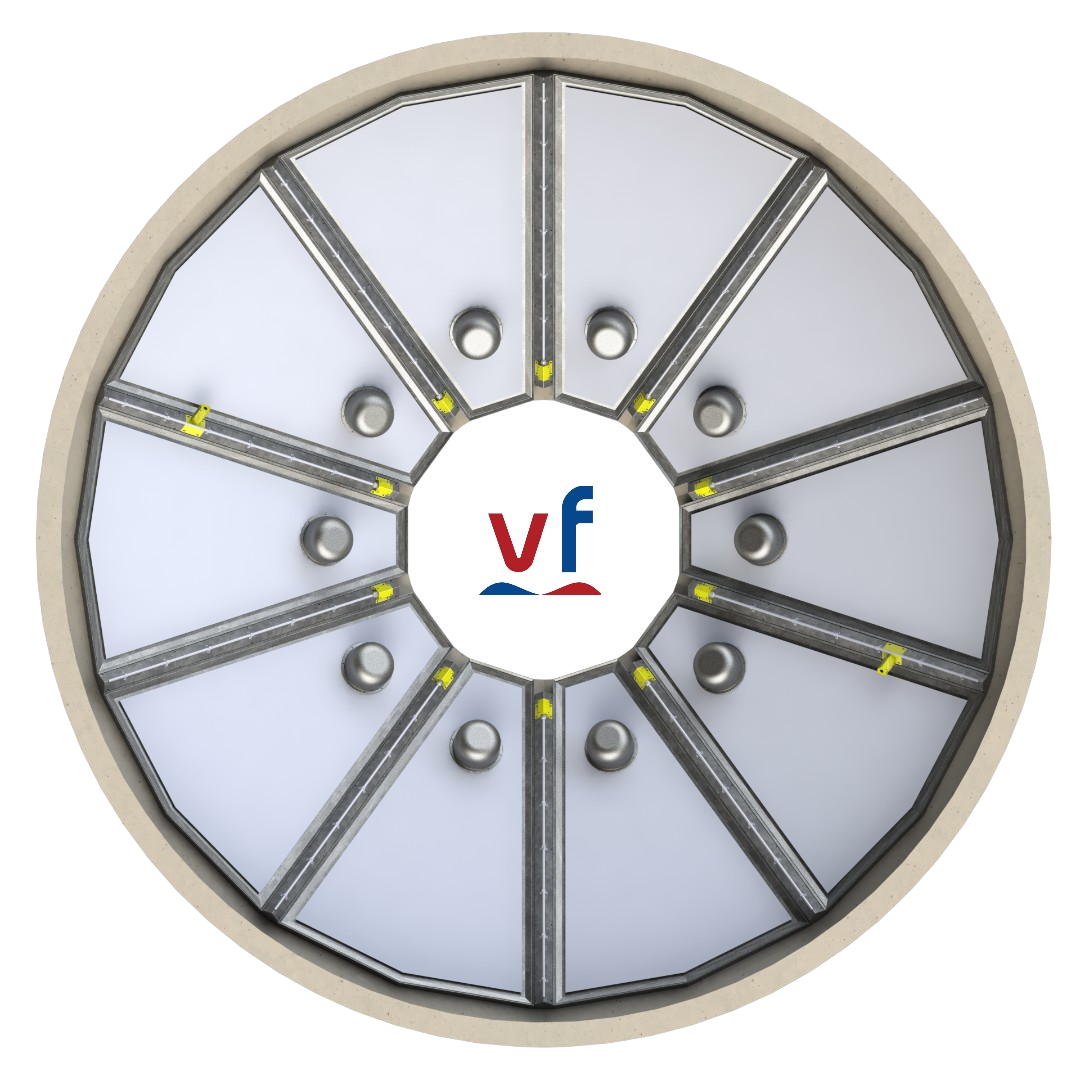

It is fully modular and can be tailored for all geometries, both for new silos and renovation projects, including flat bottoms with an added slope structure.

Smart Design

Each vibrating floor is made up of autonomous modules, each one reacting automatically to the presence of product and to the flow conditions.

This modularity not only allows intelligent operation, but also provides redundancy: unloading remains possible even if a module is at a standstill.

Safe, efficient and intelligent, the Vibrafloor system has already proven its value in a multitude of applications all around the world.

Quality Manufacturing

Our vibrating floors are all designed and assembled in our factory in Dracy-le-Fort, Burgundy, from materials produced mainly locally or on the national territory, enabling a strong integration of our suppliers.

Safe Operation

In terms of safety, the Vibrafloor system eliminates the need for human intervention inside the silos, thus protecting personnel from major risks inherent to this hazardous environment. The Vibrafloor system is also available for ATEX zone 20.